Description

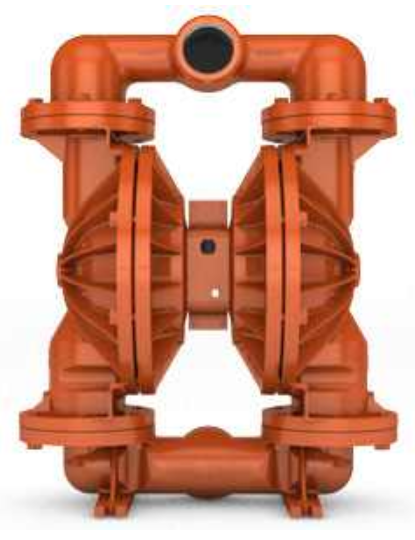

Diaphragm pumps generally work best for clean liquids and harsh chemicals in low-pressure applications, whereas peristaltic hose pumps perform better with thick or dirty fluids containing particulate material, bubbles or trapped gases, especially in high-pressure applications, yet the hose must be monitored to prevent leaks.

Diaphragm pump characteristics:

- have good suction lift characteristics, some are low pressure pumps with low flow rates; others are capable of higher flow rates, dependent on the effective working diameter of the diaphragm and its stroke length. They can handle sludges and slurries with a relatively high amount of grit and solid content.

- pump design separates pump fluids from potentially sensitive internal pump parts

- internal pump parts often within oil, suspended and isolated, to promote pump longevity

- suitable for abrasive, corrosive solutions

- suitable for discharge pressure up to 1,200 bar

- have good dry running characteristics.

- can be used to make artificial hearts.

- are used to make air pumps for the filters on small fish tanks.

- can be up to 97% efficient.

- have good self priming capabilities.

- can handle highly viscous liquids. A viscosity correction chart can be used as a tool to help prevent under-sizing AOD pumps

- can pump corrosive, abrasive, toxic, and flammable liquids

Advantages include:

- No Electricity: These pumps operate via compressed air. This means that they can be used in environments where an electrical supply is not suitable i.e. in hazardous areas.

- Simplicity: Without requiring complicated wiring, and no need to have an electrical control, AODDs are easy to install and operate. In fact, they are much easier to use than many other pump types.

- Run Dry: AODD pumps can run dry without damaging the pump or cause any issues. Some other pump types will always need to stay primed and not run dry or they will either damage the whole pump or some of the parts, resulting in a costly rebuild. Here is some of those pump types that can not run dry:

- Viscous liquids: Air operated double diaphragm pumps can handle a variety of fluid viscosities. Having a pump which can transport both high and low viscous materials means that a pump can be used for a variety of tasks. Some other pump types cannot handle highly viscous fluids and will stop working or breakdown under the same conditions.

- Abrasive Materials: Just as with handling low and high viscosities, an AODD pumps can also process corrosive or abrasive fluids, as well as more solid or powdered materials.

- Gentle pumping: These diaphragm pumps have no impellers or other moving parts exposed to the liquid being pumped, which means that they are suited for transporting shear sensitive media.

- Safety: All of the above combined, also means that an AODD pumps is a great option when pumping volatile or dangerous liquids.

Reviews

There are no reviews yet.